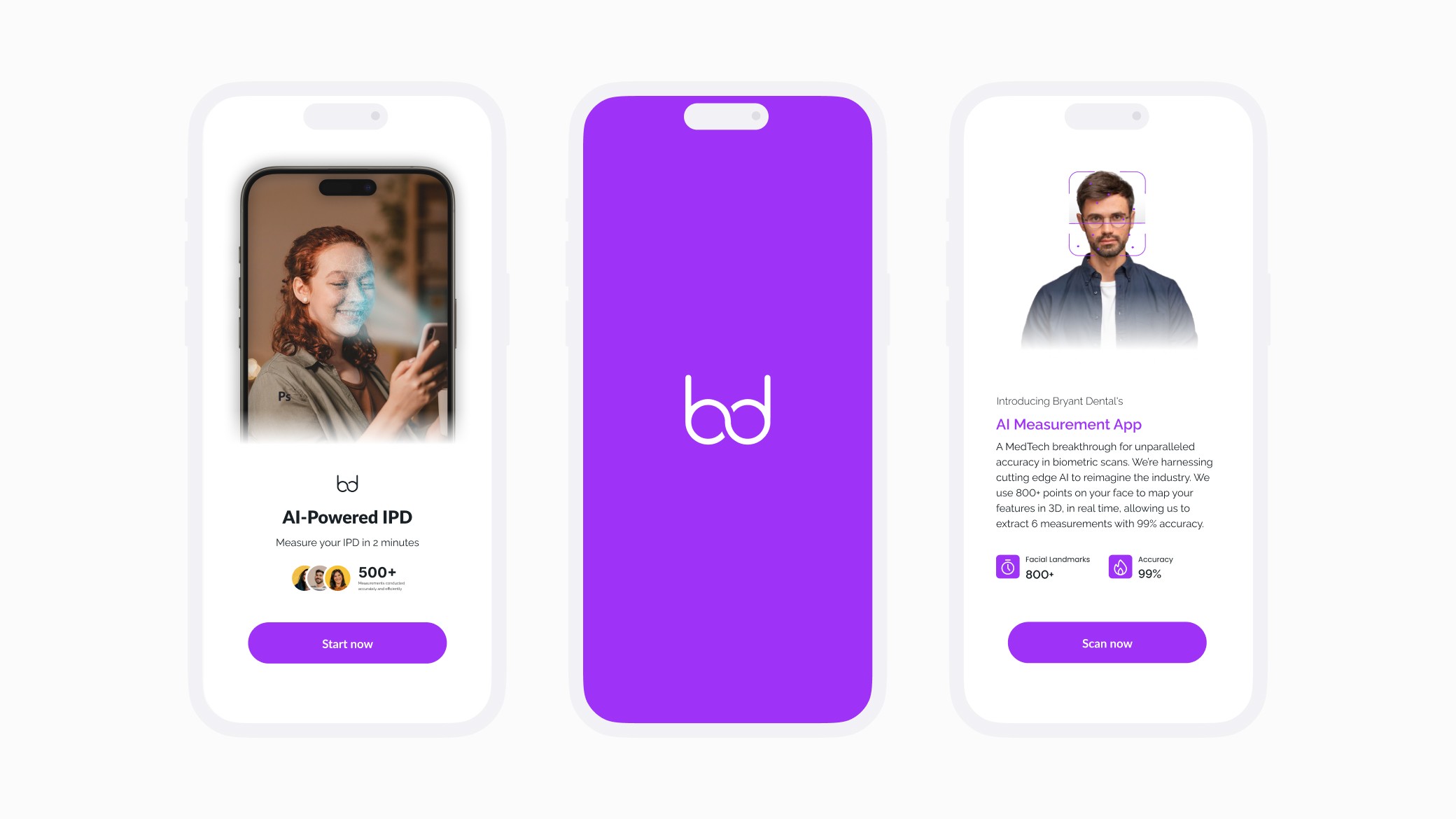

AI-Powered IPD

2024

ransform the traditional, manual process of measuring inter-pupillary distance (IPD) for custom ergonomic loupes into a seamless, digital solution. This aimed to reduce costs, eliminate the need for physical kits, and accelerate production timelines.

Role: UX/UI Designer/Product Owner

Focus Areas: User research, wireframing, prototyping, AI integration, production system integration, and product strategy

Challenge

Inefficient Traditional Process: Customers were required to use physical measurement kits, leading to shipping delays and manual data submission.

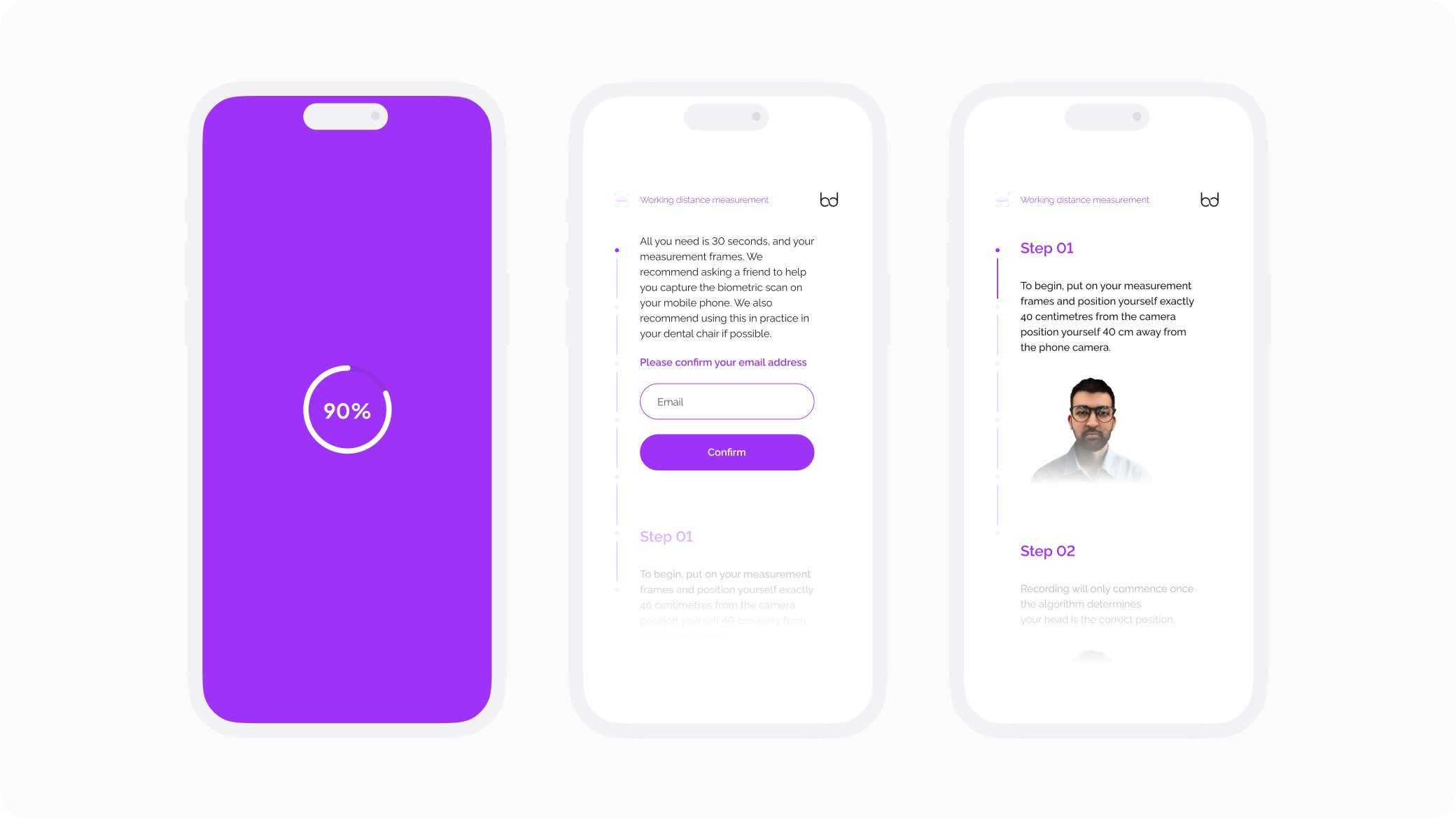

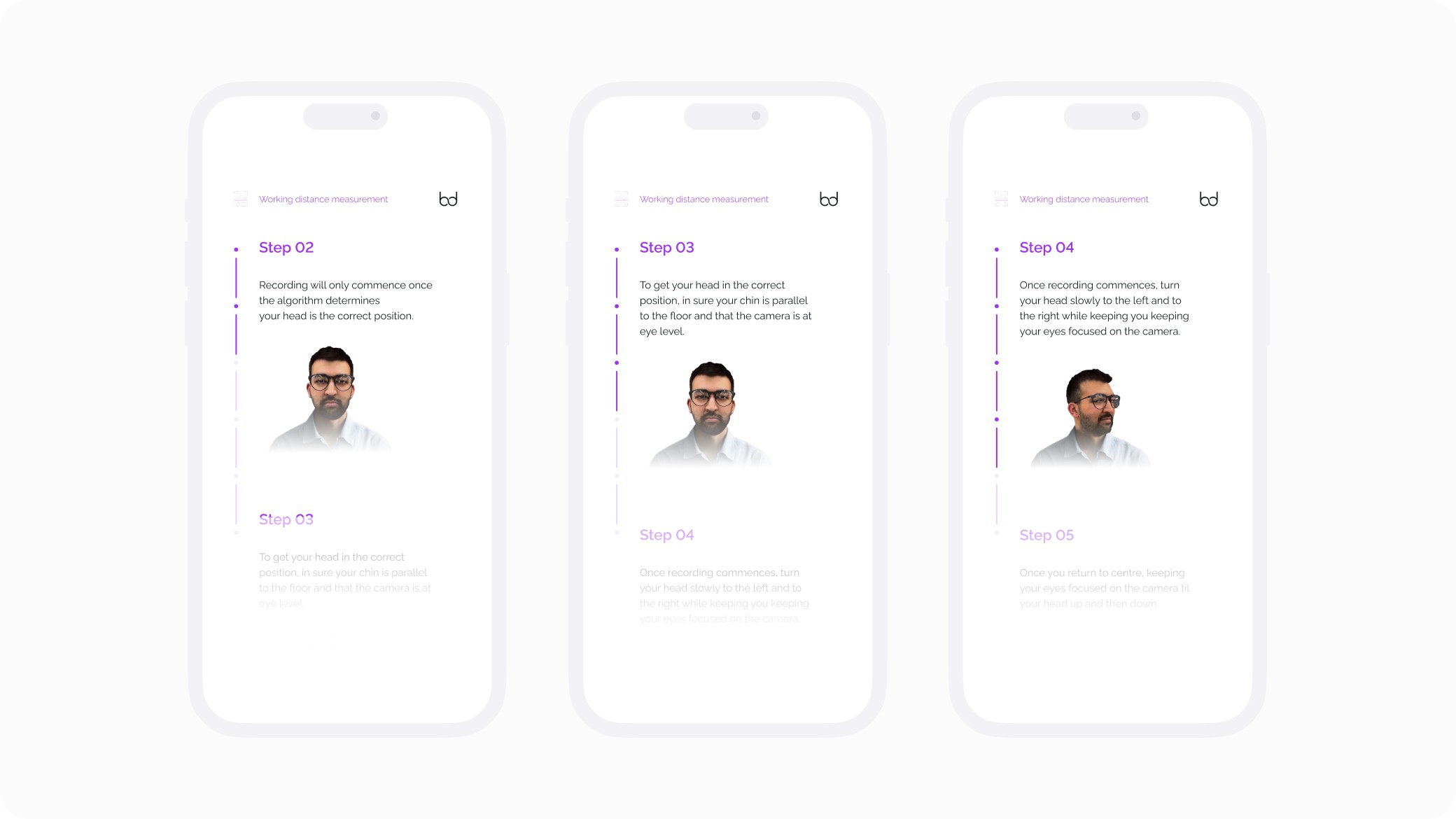

User Accessibility: Ensuring the new digital solution was intuitive and accessible, particularly for non-technical users.

Accuracy of Measurements: Maintaining or improving the precision of IPD measurements through digital means.

Strategy and Design Approach

As UX/UI Designer:

Comprehensive Research: Conducted extensive research into existing facial scanning technologies, customer pain points, and industry best practices for measurement accuracy.

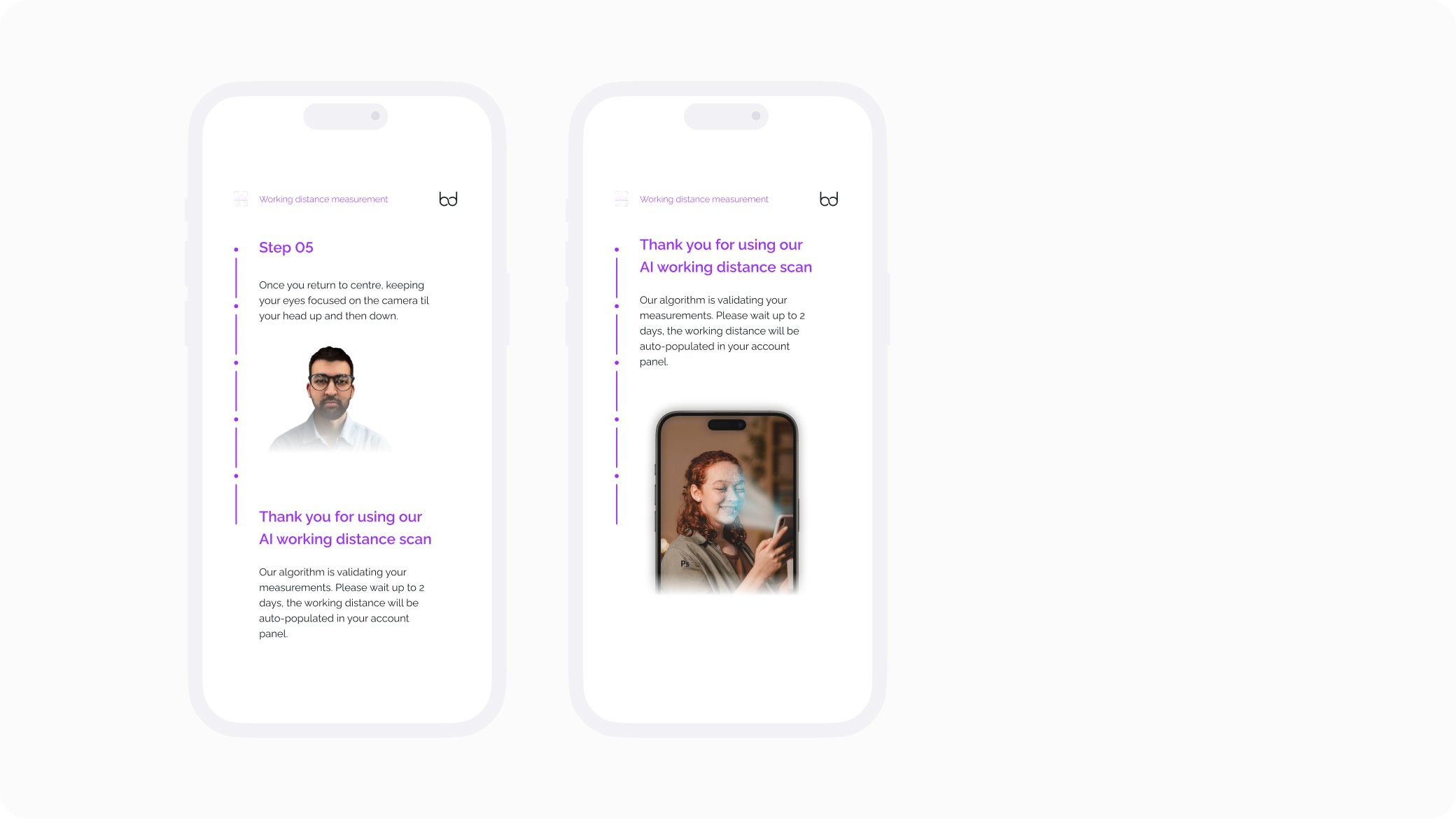

User-Centred Wireframing: Designed wireframes emphasising an intuitive user flow, guiding users through the scanning process with clear, step-by-step instructions.

Prototype Development: Developed a prototype incorporating AI-based facial scanning, enabling users to capture over 800 facial landmarks via their smartphone camera for precise IPD measurements.

As Product Owner:

Defining Product Vision and Strategy: Articulated a clear product vision aligned with strategic objectives, identifying market opportunities where AI provided a competitive edge, and defined a roadmap to guide the development team.

Prioritising the Product Backlog: Managed the product backlog, prioritising features critical to the project’s success, balancing stakeholder requests with project constraints to ensure timely and within-budget delivery.

Stakeholder Communication and Management: Served as the primary point of contact between the development team and business stakeholders, ensuring clear communication and managed expectations.

Ensuring Compliance and Ethical Considerations: Oversaw compliance with relevant regulations and ethical standards, particularly in areas like data privacy, bias, and transparency

Outcomes

Elimination of Physical Kits: Successfully replaced the need for physical measurement kits, leading to significant savings in shipping and material costs.

Accelerated Production: Streamlined the transition from measurement to manufacturing, resulting in faster order fulfilment.

Enhanced Customer Satisfaction: Improved the overall customer experience by providing a quick, accurate, and user-friendly measurement process.